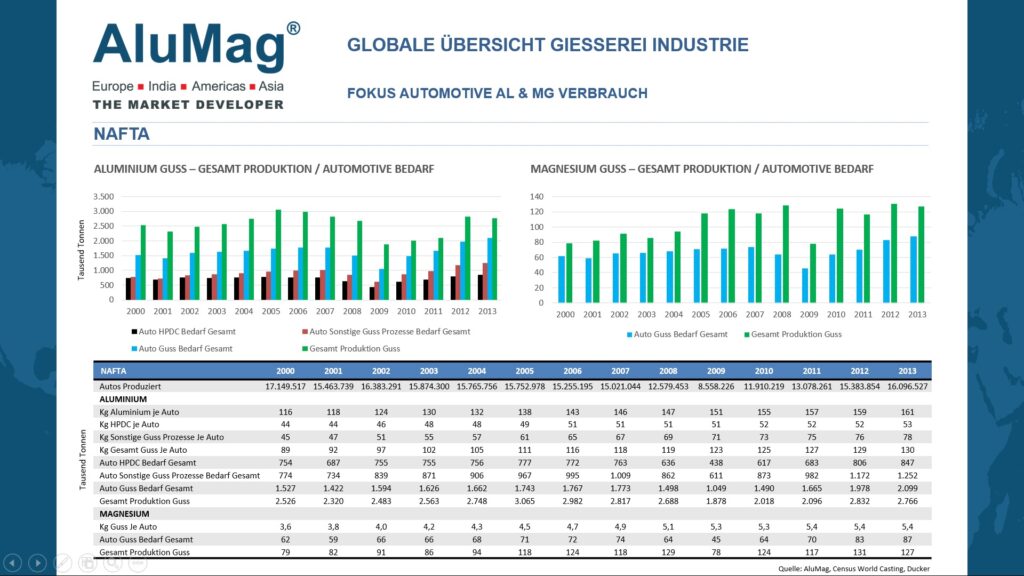

Global Non Ferro Casting Industry Analysis

SNAP SHOT SUMMARY EXTRACTION:

Cast aluminum is primarily used in power train applications, such as cylinder heads, engine blocks and transmission housings. In NA about 85% of all vehicles are equipped with an aluminum engine block. In Europe, this figure is 55%, 60% in China and 45% in Brazil [2015]. For 2020, a penetration rate of 89% in NA is expected.

Another important application is cast aluminum wheels, currently around 45% of all vehicles sold are equipped with original cast aluminum wheels world wide. In NA, the OE incorporation rate is of 77% [2015]. For 2025 OE penetration rate of 50% is expected worldwide.

When it comes to BIW structures, especially sports cars are equipped with cast aluminum [vacuum HPDC] since the 90s. Audi initiated the turn with the introduction of an aluminum frame for medium to high Volume vehicles [A8 and A2] beginning of this millennium. The Audi “space frame“ Was made of cast-, extruded- and sheet aluminum processed parts. With a very high growth rate of applications in the automotive structure, aluminum is no longer a rarity. New generations of models of high-end car manufacturers such as MB [C,E, and S-Class], BMW [X5, X6, 5 & 7-Series], JLR [Range Rover, Range Rover Sport, XJ, F-Type, XE] Cadillac [ATS, CTS, CT6], Audi [Q7, A4, TT, A8, A6] have ..

–